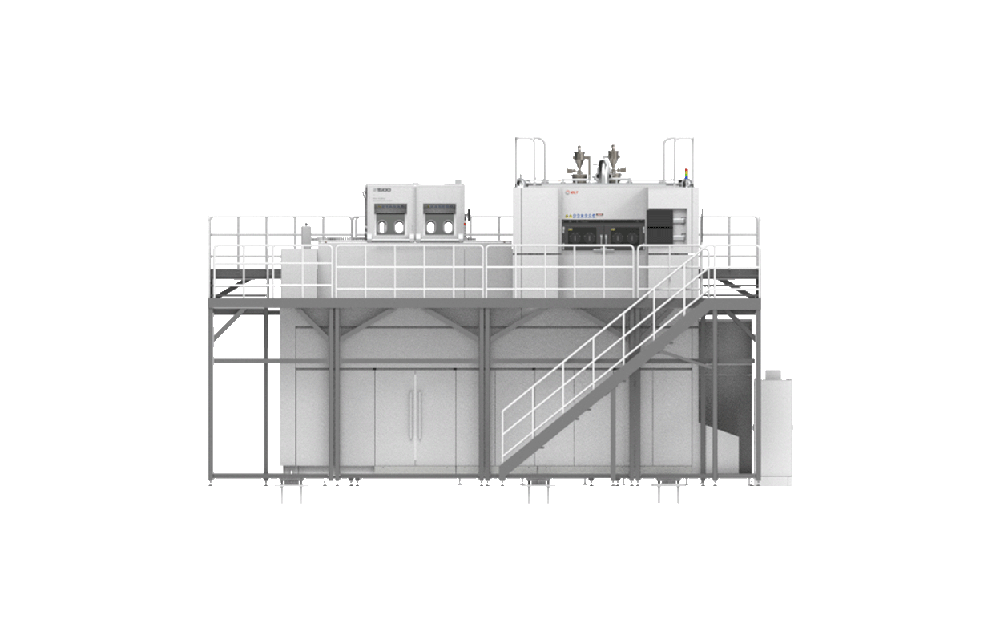

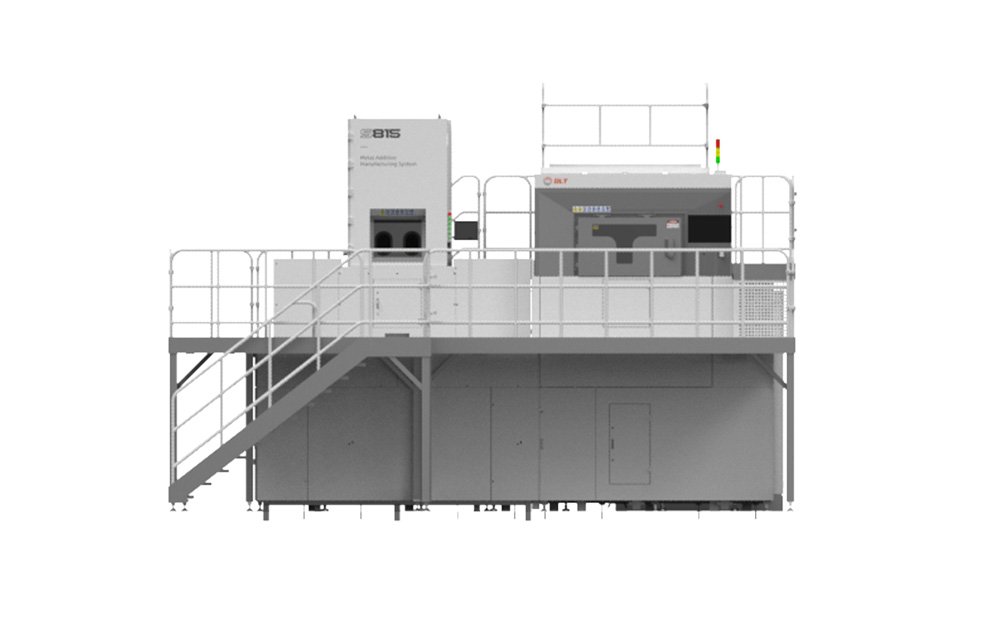

BLT-S815

"Manufacturing" with Sincerity

-

CE Safety Certification

-

Laser FDA Safety Registration

-

ATEX(Explosion Proof) Certification

-

ISO9001:2015 / ISO14001:2015 / ISO45001:2018

-

Supporting Materials

Titanium Alloy, Aluminum Alloy, Superalloy, Stainless Steel, High-strength Steel -

Build Dimension(1)

800mm×800mm×1500mm(W×D×H) -

Laser Power

500W×6; 500W×8; 500W×10 -

Building Speed(2)

150cm3/h; 200cm3/h; 250cm3/h;

-

Aviation

-

Aerospace

-

Automotive

-

Engine

(1)Excluding substrate thickness.

(2)Dependent on part geometry, material and parameter set used.

*The displayed products are provided for reference purposes only.

* The actual models available may vary according to the product listings in each specific region.

(2)Dependent on part geometry, material and parameter set used.

*The displayed products are provided for reference purposes only.

* The actual models available may vary according to the product listings in each specific region.

Advantages

-

Multi-beam Lasers Splicing

The building quality of each area is consistent -

Long-term?Filtration? System

Automatic blowback cleaning

Long filter life -

Self-adapting Powder Spreading Correction

Deep learning technology

Intelligent powder spreading and correction -

More Scanning Strategy

Variable overlap position

Select different scanning strategy -

Automatic Circulation of Powder

Powder closed-circulation processing system

Automatic recycling sieving and supply -

Safe Handling of Powder

Handle full-height parts through pickup cabin with inert gas atmosphere

Multi-station for powder cleaning to ensure safety -

Safe and Continuous Production

Easy and quick printing preparation

Automatic powder circulation in the printing process cleaning to ensure safety

Related Cases

1/1

Intelligent Modules Help You

Achieve More

Standard Functions

- Diagnosis Fault-grading

- Process Data Traceability

- Equipment Status Self-test

- Height Self-checking on Parts

- Recoating Detection

- 3D Reconstruction

Optional Functions

- BLT-MCS Connect

- BLT-MES System