Because of their low density, high specific strength, high specific stiffness, and good plasticity, aluminum alloys are the preferred materials for achieving lightweight structures. In the aerospace industry, additive manufacturing of aluminum alloys is a promising solution because parts require extremely light and high strength. However, the limited mechanical properties of aluminum-silicon alloys currently hinder their application. The cracking tendency of high-strength aluminum alloys and the high cost of rare earth elements have brought challenges to the large-scale application of such materials in additive manufacturing.

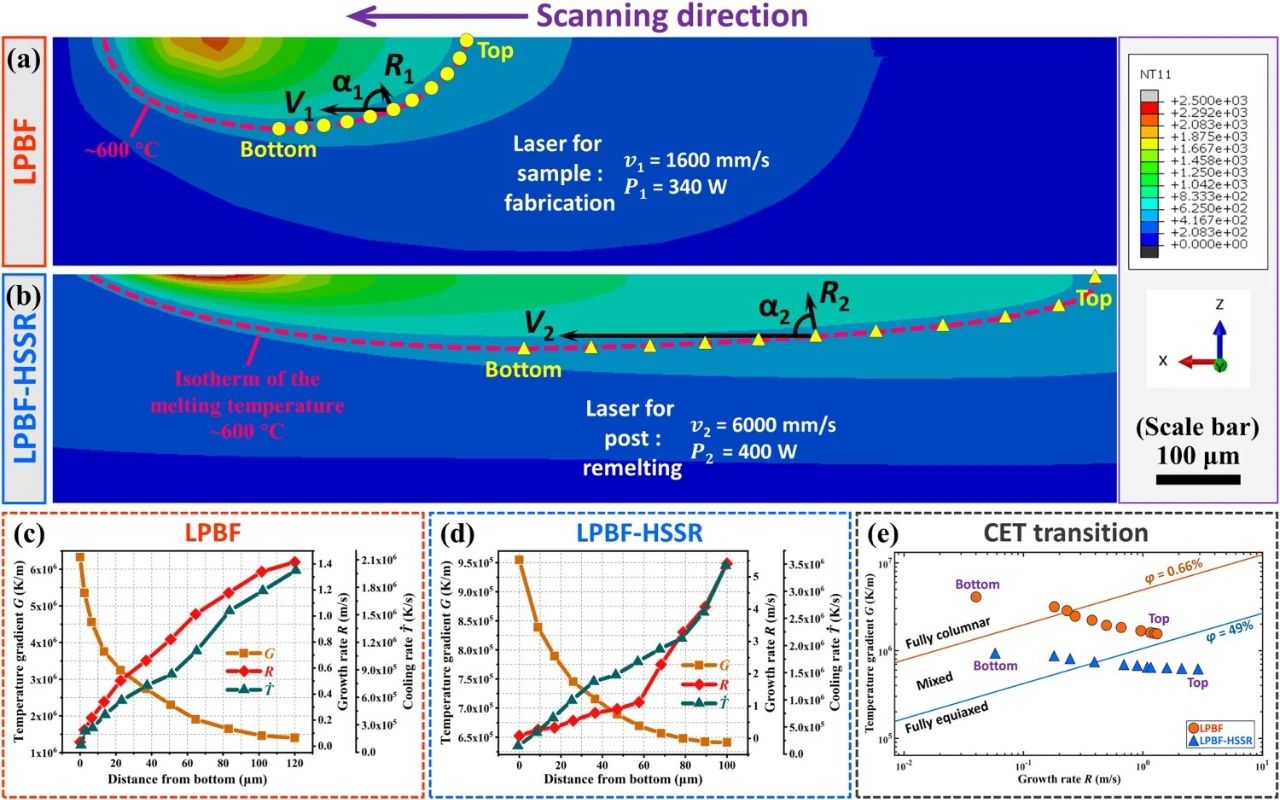

Recently, to address the above problems, Professor Lin Xin’s team at Northwestern Polytechnical University proposed an in-situ high-speed remelting method (HSSR) to simultaneously improve the strength and plasticity of AlSi10Mg alloy produced by PBF-LB/M process. This method uses the heat accumulation in the initial melting stage to alleviate the temperature gradient in the molten pool and increases the solidification rate in the high-speed remelting stage, promoting the grain/honeycomb substructure refinement, columnar to equiaxed transformation (CET) and precipitation of nanoparticles. Compared with aluminum alloys/composites processed by PBF-LB/M process and other methods to date, the resulting materials show excellent strength-plasticity synergy. The research “Achieving superior strength-plasticity performance in laser powder bed fusion of AlSi10Mg via high-speed scanning remelting” was published in Materials Research Letters (IF 8.8).

The researchers used BLT-S210 to prepare samples and conducted comparative studies on PBF-LB/M process samples and high-speed remelting strategy (HSSR) samples, which verified the ideas of the paper and drew research conclusions, As a “brilliant research tool,” BLT-S210 has precise forming accuracy control, a stable and reliable optical system, and a uniform and continuous wind field. Its excellent performance can flexibly respond to diversified needs and provide solid and reliable technical guarantees for the smooth advancement of scientific research projects.

So far, BLT has delivered more than 100 BLT-S210 to clients, promoting cutting-edge research on new materials, new structures, and new functions of metal 3D printing. BLT is deeply engaged in the field of scientific research and is committed to providing machine & system, technical consulting, cutting-edge applications, and other products and services to universities and scientific research institutions, helping Tsinghua University, Peking University, Shanghai Jiaotong University, Beihang University, Northwestern Polytechnical University, and Artificial Intelligence and Robotics Innovation Center of the Hong Kong Innovation Institute of the Chinese Academy of Sciences, among others, to achieve breakthroughs.